CNC Machining

We excel in CNC milling with a comprehensive range of capabilities. Our state-of-the-art facility features both Vertical and Horizontal Milling machines equipped with 3, 4, and 5-axis capabilities. This versatile setup allows us to handle a wide variety of projects and materials with precision and efficiency. Our machines can accommodate sizes up to 1500mm x 1500mm x 1500mm (60" x 60" x 60"), enabling us to produce intricate components across different industries, including aerospace, medical, energy, and more. Whether you require prototyping, small batch, or large-scale production, our CNC milling services ensure exceptional quality and reliability tailored to your specific needs.

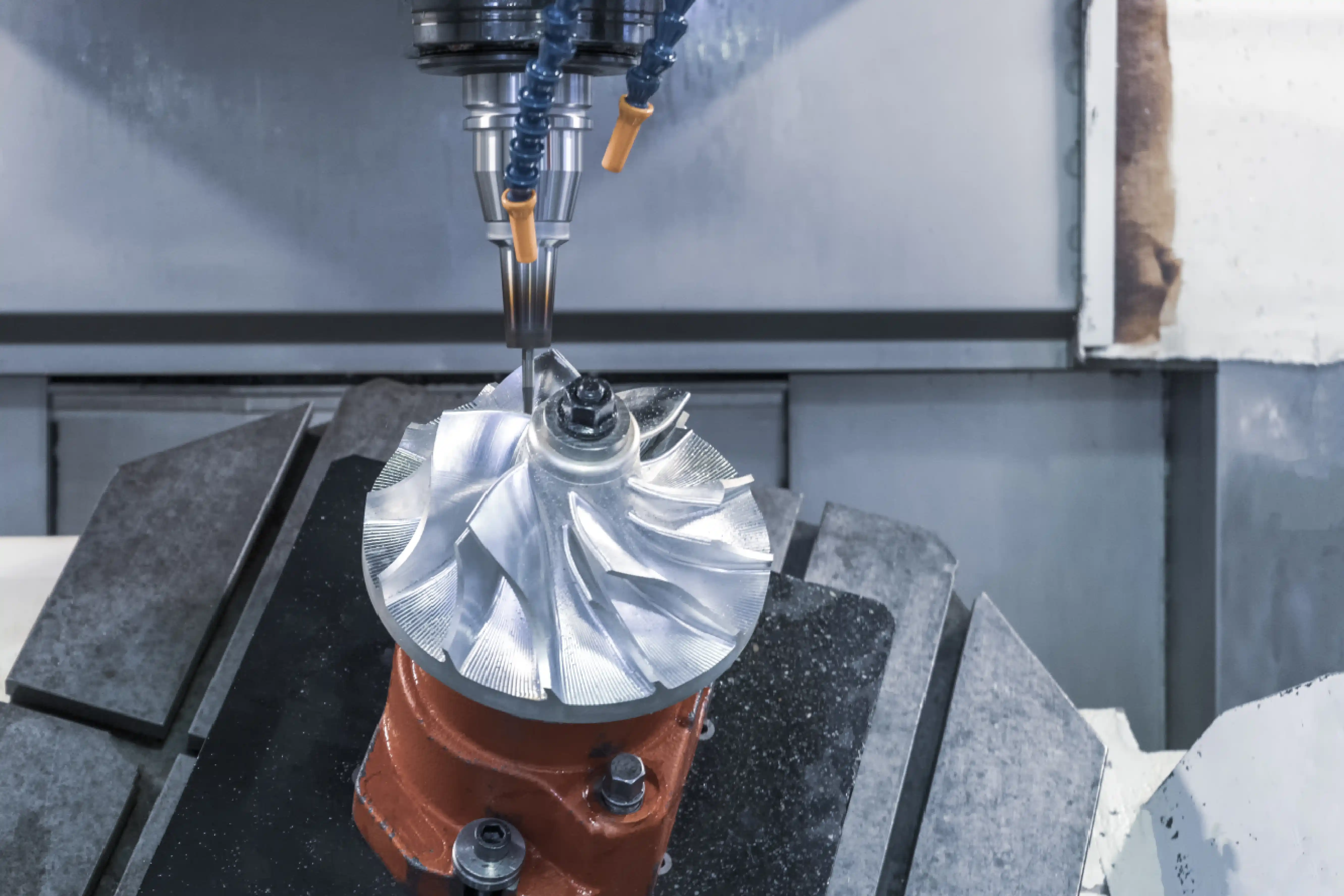

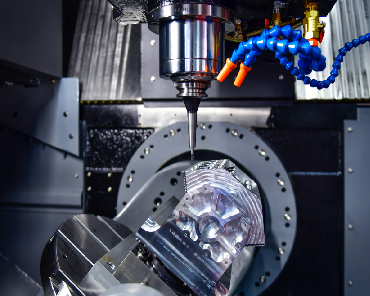

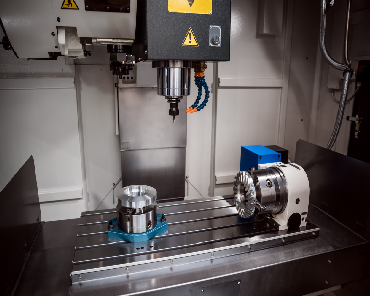

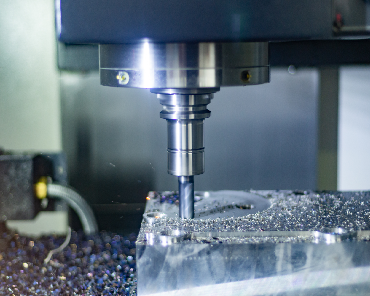

CNC Milling

5 Axis

4 Axis

3 Axis

Horizontal Machining Center (HMC)

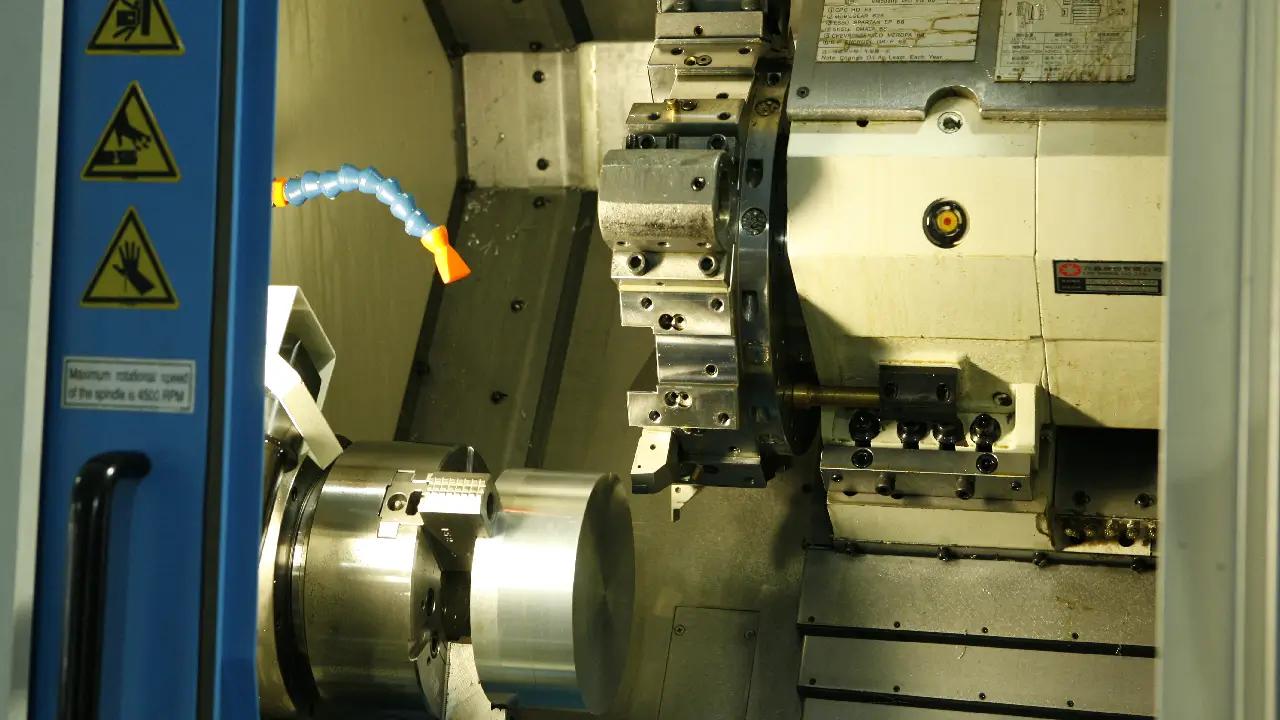

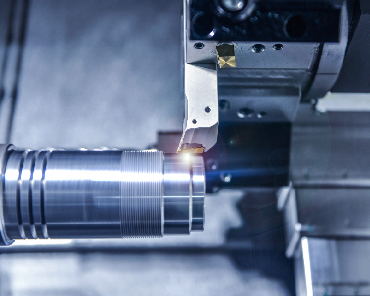

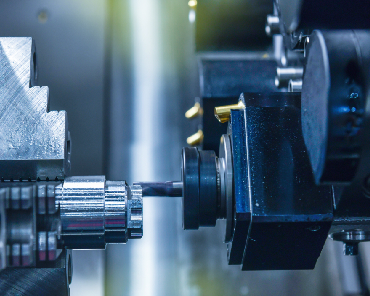

CNC turning is a cornerstone of our manufacturing capabilities. Utilizing advanced CNC lathes, we specialize in transforming raw materials into precise cylindrical components with unmatched accuracy and efficiency. Our CNC turning process enables us to handle a wide range of materials, from metals to plastics, meeting diverse industry needs.

CNC Turning

Turning

Turn Mill